In the Metal Injection Molding (MIM) industry, 17-4 PH stainless steel is one of the most popular materials thanks to its combination of strength, hardness and corrosion resistance.

MIM 17-4 PH is a martensitic precipitation-hardening stainless steel based on the AISI 17-4 PH standard. It is characterized by a good combination of mechanical properties and corrosion resistance.

It is common in MIM, since the mechanical properties makes it possible to design parts, which retain a good strength. The secondary hardening can to some degree be done in the sintering process by adjusting parameters.

Corrosionwise the material is on par with 304L, and can be substituted in many applications where the mechanical properties are required. Also the 304 powders are not available in bulk for MIM, so the 17-4PH is commonly used instead.

Chemical specification

The chemical composition of 17-4 PH MIM after sintering is as follows. (Measured in % of weight).

| C % | Cr % | Ni % | Cu % | Nb % | Mn % | Si % | Fe % |

| ≤ 0.07 | 15 – 17.5 | 3 -5 | 3 – 5 | 0.15-0.45 | ≤ 1 | ≤ 1 | Balance |

Typical properties

Properties can vary and can of course be adjusted to your application needs. It is however important to remember, that the properties are intercorrelated – demands on certain properties will offset values for other properties. If you e.g. have a need for higher hardness then it will influence elongation to a lower value. You have to be willing to forego other properties, if you have high demands in one area.

The challenge is to know what kind of properties are needed. Especially if it is the first times working with MIM. Many drawings are not designed with MIM in mind, but rather regular machining.

The best solution to this issue is to use our many years of design and production experience. Please consult our experts early in the process for further discussions and information regarding material selection and not least design possibilities. For some guidance however, here are the typical properties of finished sintered parts:

| Sintered | Heat treated | |

| Density [% of theoretical] | ≥ 98 | ≥ 98 |

| Yield strength Rpo.2 [MPa] | 650 – 750 | ≥ 950 |

| UTS Rm [MPa] | 800 – 950 | ≥ 1100 |

| Elongation [%] | ≥ 6 | ≥ 4 |

| Hardness [HRC] | ≥ 27 HRC | ≥ 38 HRC |

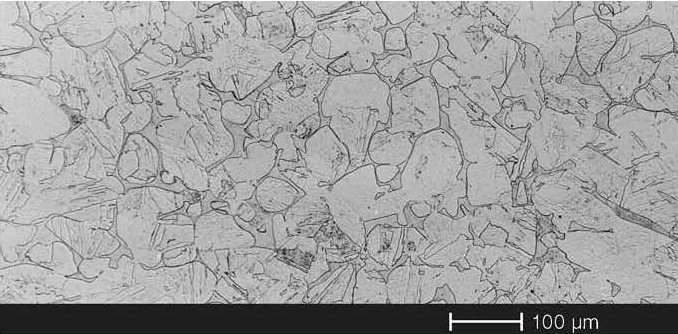

Typical Microstructure