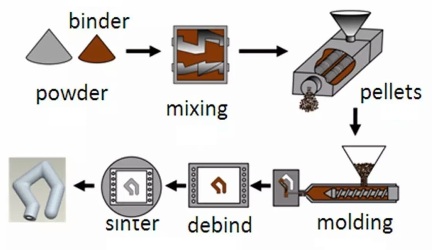

Metal Injection Molding (MIM) is a manufacturing process that involves manipulating metal powders to behave like a plastic by mixing them with polymer binders to form a feedstock. This feedstock is used to injection mold net shaped, precision components. Parts are then thermally processed to remove the binder system and finally they are sintered to a high density metal component with comparable mechanical properties to wrought materials.

Metal Injection Molding (MIM) is a manufacturing process that involves manipulating metal powders to behave like a plastic by mixing them with polymer binders to form a feedstock. This feedstock is used to injection mold net shaped, precision components. Parts are then thermally processed to remove the binder system and finally they are sintered to a high density metal component with comparable mechanical properties to wrought materials.

Intricate and complex 3D geometries that in the past have been either very difficult or very costly to produce through traditional manufacturing methods such as CNC machining, can be readily achieved with metal injection molding and at significantly reduced prices and lead-times.