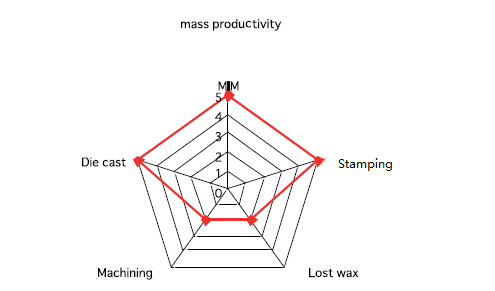

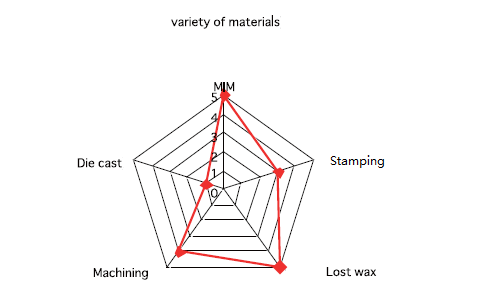

MIM is a process that merges two established technologies: plastic injection molding and powdered metallurgy. It is capable of producing precise, complex parts in large quantities with metals that are not capable of being die cast—like stainless steel and other low alloy steels. There is a place for each of the traditional metal-forming processes: each has its own strong suits as well as its limitations. But wherever a component fabrication choice exists between MIM and one or more of the other processes, it pays to see how they stack up in a head-to-head comparison.

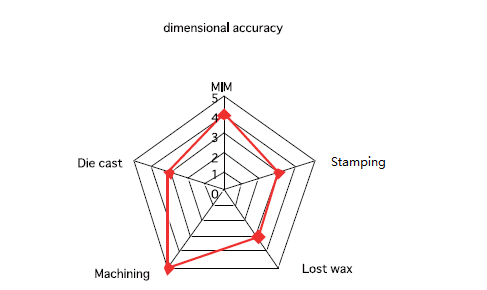

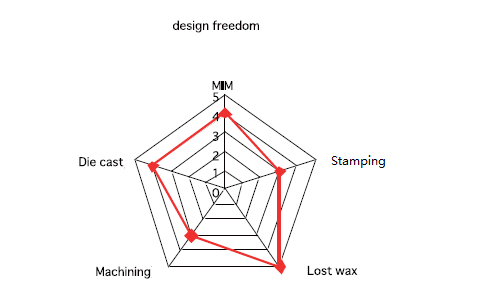

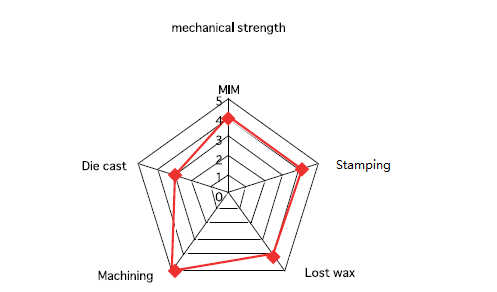

The following tables show how the four major processes fare in some of the more important parameters to consider.

MIM vs. other Processing Methods

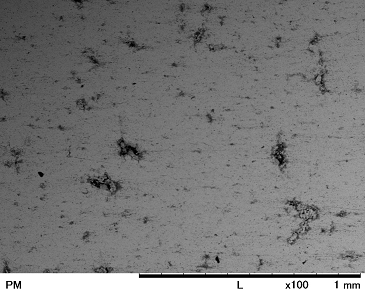

MIM vs. PM

∗ The above descriptions are intended to serve only as guidelines. The actual properties of products will

vary depending on the materials used and/or their shapes.