Metal Injection Molding (MIM) process is ideally suited to the type of product, which demands complex, light, thin and small-scale designs to be produced in large quantities to net-shape. FineMIM provides innovative technical solutions to reduce product cost, improve product quality, and improve process efficiency by using of ingenuity, creativity and different way.

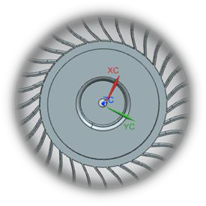

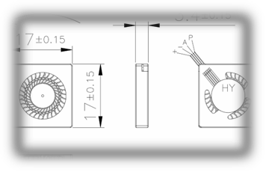

1. Project: Super Thin Metallic CPU Fan

Technical Challenge:

- 33 vanes, 0.15mm thickness

- Vane deformation: 0.05mm

- Tolerance:±0.02mm

Technical Solutions :

- Creative ejection design

- Special mould gates design

2. Project: Assembly Part in Wearable Devide Band

Technical Challenge:

- 6 MIM parts assembly into one

- Extremely smooth surface

- Tolerance:±0.02mm

- Deformation Control: 0.05mm

- Lightest part weight: 0.08g

Technical Solutions :

- Design Changes: 20 times

- Trial Assembly: 8 times

- Mass Production: 35 Mpcs

3. Project: Hinge-High Volume Production

Technical Challenge:

- 5 MIM parts assembly into one

- No crack inside

- Tolerance: ±0.05mm

Technical Solutions :

- Design Changes: 45 times

- Trial Assembly: 8 times

- 500Kpcs/D in very short period of time

- CCD Inspection