Introduction

The Metal Injection Molding process is a net shape process that forms and sinters metal powder to create high strength components. It is a cost effective process when components are in need of high strength and wear characteristics that other processes are not able to achieve.

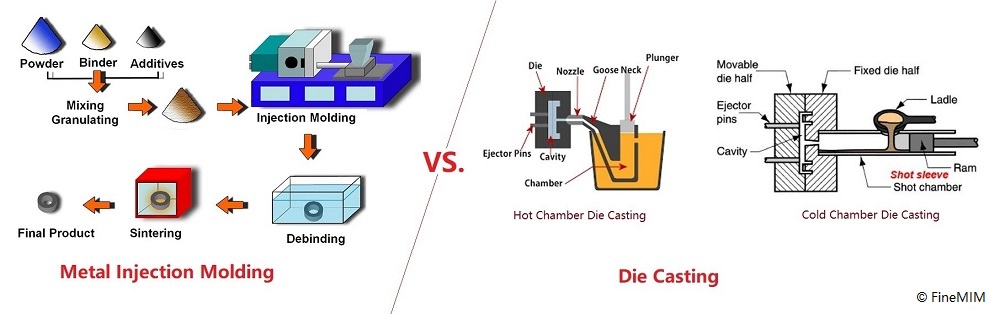

Although both the MIM and die casting processes consist of injecting metal into a die, this is where the similarity ends. Die casting has several economic advantages, which in the right circumstance and component, may offer large cost savings opportunities for the component designer.

Property Comparison

Although there are some variations in technique, the major difference between die casting and metal injection molding is that die casting uses some kind of metal, often an aluminum alloy or zinc alloy, as the raw material, while metal injection molding uses steel or other types of MIM alloys. The most common alloys are stainless steels, titanium, nickel, tungsten, copper and other various combinations.

Process Comparison

The die casting process is the fastest and most economical way to form high volumes of net-shape components. The zinc alloying process consists of mixing zinc with essential elements such as aluminum, copper and magnesium into an ingot which is then shipped to the die casting facility. At the die casting plant, the ingot is melted either at the die casting machine or in a central furnace and transported to the die casting machine. During the “hot chamber” die casting process, the pump (which is immersed in the molten alloy) pushes the alloy through the die casting machine and into a die. Cycle times are dependent on the size of the component, but can range from a second, up to approximately 30 seconds.

The MIM process is a more intensive process. In this process, the metal alloy is first formed into a fine powder and then mixed with a thermoplastic binder to form a feed stock. The feed stock is shipped from the supplier to the injection molding plant where it is heated, injected into a mold, cooled and finally ejected from the mold. The next step is a de-binding process where a catalyst is used to remove the binder. This is followed by a sintering process where the part is put into an oven at a temperature close to the melting temperature of the metal allowing the fine metal powder to sinter together, leaving a strong net-shape component.

Although the MIM Process can produce higher strength components than die casting, the process is been found to be much more costly than the die casting process. This cost differential depends on the type of alloys chosen, but our experience is that the die casting process has been found to be at least 30% less expensive. In addition, it is published that the typical die life for MIM alloys is about 150k – 300k shots (depending on size and shape of component). The zinc die casting process reports a typical die life of over one million shots. So, in addition to standard processing costs, additional costs in die life can be achieved with the zinc die casting process.

Also, during the debinding and sintering stage up to 30% shrinkage can occur in the MIM process. The patternmaker’s shrinkage for zinc die casting is approximately 0.007” per inch. This isotropic shrinkage that occurs in die casting eliminates some of the MIM related tool making challenges and costs. There are also many other component design advantages to the zinc die casting process over MIM including linear tolerance, draft, size limitations, isotropic shrinkage, etc. These may be discussed in detail in a subsequent articles.

Summary

The MIM process is a very interesting and cost effective method to create high strength, net-shape components. It is less expensive than many alternative processing techniques such as machining. It is however, more expensive than the die casting process, as many of the MIM alloys are stronger and harder than most of the zinc die casting alloys.