1. Introduction

Powder Injection Molding (PIM) is a technology for manufacturing complex, precision, netshape components from either metal or ceramic powder. The potential of PIM lies in its ability to combine the design flexibility of plastic injection molding and the nearly unlimited choice of material offered by powder metallurgy, making it possible to combine multiple parts into a single one. Furthermore, PIM overcomes the dimensional and productivity limits of isostatic pressing and slip casting, the defects and tolerance limitations of investment casting, the mechanical strength of die-cast parts, and the shape limitation of traditional powder compacts.

Due to the demand of high performance materials and the miniaturization of complex components in various fields, PIM market has exceeded the $ 1 billion mark in 2007, becoming approximately six times larger than 15 years before. This impressive growth rate is not expected to slow down in the next few years, as a recent report from Global Industry Analysts announced that together, world metal and ceramic PIM market is forecast to reach $ 3.7 billion by the year 2017 (Global Industry Analysts [GIA], 2011). Metal injection molding (MIM) is still considered the largest segment of this market, accounting for more than 70% of global output. Although PIM is globally widespread, Europe and Asia-Pacific account for a major share of MIM segment, while USA is still the largest market for Ceramic Injection Molding (CIM).

In Europe, the MIM production is dominated by automotive applications and the so called consumer market (which includes watches and eyeglasses), while the North American production is mainly applied to the medical/healthcare field. On the other hand, the Asian production, considered the largest one, is dominated by consumer electronics and information technology applications. The consumer electronics market is, indeed, one of the drivers behind MIM, whose growth is largely taking place in Asia, specifically in Taiwan, Malaysia, Thailand, China, Singapore and South Korea. Another growth factor is the expansion of medical component production also in Asia, as a larger population gains access to improved health care.

A recent increase in MIM sales has generated a need for new equipment, with a simultaneous investment in research and development. Typically, leader companies invest an average of 10.5% of sales in the combination of capital expansion and research. Besides this, several contract electronic assembly firms that used to purchase MIM components from custom molders have now elected to make from MIM a captive operation. This could lead to rapid growth for those operations since the relationship between design and production can be improved.

Stainless steel continues to dominate MIM applications, accounting for around half of the global production, reflecting the capture of components that would have otherwise gone to investment casting. Nevertheless, other materials as copper, nickel alloys, bronze and more recently tungsten alloys and titanium also represent important markets. On the other hand, the CIM market is mainly dominated by products made out of alumina, zirconia, and silicon or aluminium nitride powders.

Typical components produced by PIM, either MIM or CIM, range from 0.002 to over 100 g. Furthermore, in both segments it is clear the progressive move towards smaller products, demanding improved technologies regarding machinery, process, and materials, hence leaving a still open field for applied research.

2. Overview of PIM process

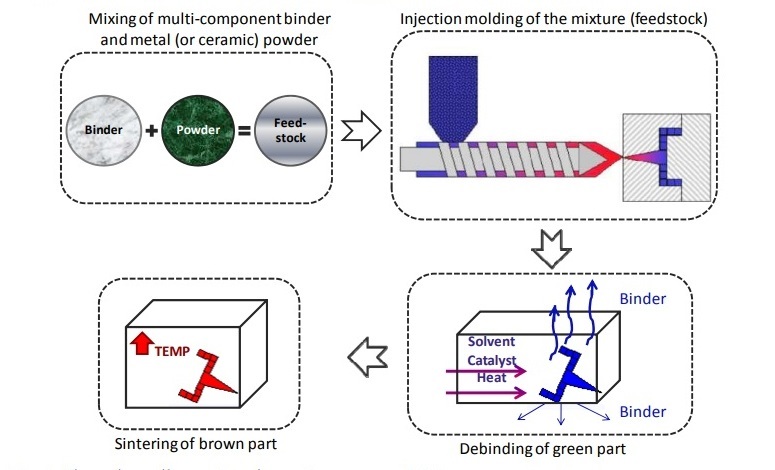

The PIM process presents countless variations which are used in the industry today. Invariably, it consists of four steps:

- Feedstock preparation;

- Injection molding;

- Debinding;

- Sintering

The starting material for PIM, usually termed feedstock, is a homogeneous pelletized mixture of metal or ceramic powder and an organic multi-component binder. The binder and the powder are combined in a variety of compounding equipment, such as extruders and mixers. The mixture is then pelletized to an appropriate shape for feeding into the molding machine. The binder is simply a carrier medium for the powder and once a part is molded, the binder is removed in a subsequent step.

The injection molding process is mainly identical to conventional plastic injection molding. Nevertheless, some machine hardware changes are usually required to process a specific feedstock based on their compressibility and viscosity. Control of the molding process is vital for maintaining tight tolerances in subsequent steps. Most design advantages of PIM technology are captured during molding by relying on the flexibility of incorporating complexities in the tool. A molded part is called a “green part” and is oversized to allow shrinkage during sintering.

Before sintering, it is necessary to remove the binder from the molded part. The debinding is the most expensive and time-consuming stage in the PIM technology. This removal process should be based on a progressive opening of the surface channels to facilitate the removal of vapors inside the nucleus. Three main methods can be applied depending on the composition of the binder: thermal, solvent, and catalytic. In thermal debinding, the binder is removed by degradation, evaporation, or liquid extraction, at temperatures ranging from 60 to 600 °C. The relatively long time associated with thermal debinding is greatly reduced using an organic solvent or in some cases even water to dissolve the soluble components of the binder, in the so called solvent debinding. The catalytic debinding, in turn, focus in a solid-to-vapor catalytic degradation, as it is the case of exposing acetal-polyolefin-based feedstocks to acid vapors, resulting in much faster binder removal and superior handling strength when compared to thermal or solvent debinding. Nevertheless, it is worth to point out that in all debinding methods, a skeleton of backbone binder often remains to impart adequate strength and shape retention up to the onset of sintering. This remaining backbone is thermally removed between 200 °C and 600 °C in a pre-sintering step.

Sintering is the last stage of the process, providing the inter-particle bonding that generates the attractive properties from otherwise loose powder mass. Depending on the material, debound parts or “brown parts” are sintered at temperatures ranging from 1200 to 1600 °C. It is essentially a removal of pores, accompanied by growth and strong adhesion among the adjacent particles, causing the retraction of the product whose dimensions usually reduce between 14 and 20%. Therefore, green parts are oversized to compensate for the sintering shrinkage. The fine particle size used in the PIM process results in high sintered density ranging from 95% to 99.5% of theoretical, thus providing superior mechanical and corrosion properties as compared to press and sinter technology.