Metal injection molding (MIM) is a hybrid technology that integrates the shaping capability of plastic injection molding and the materials flexibility[……]

Tag: MIM

MIM (“Metal Injection Molding”), is a forming technology that is typically used to create small, thin, light and/or complex mental parts with certain desired metal properties for use in a variety of industries and applications. MIM is often used by customers who require metal parts to be of a precise size, shape, weight and durability for functional or aesthetic reasons and in large volumes.

Metal Injection Molding vs. Investment Casting

Investment casting, also known as lost-wax casting, is one of the oldest metal working techniques, and refers to the process in which molten metal is[……]

Metal Injection Molding Expands Ahead of U.S. GDP

The U.S. metal injection molding industry is steady with annual growth rates up to 5 percent, according to a new report from the members of the Metal[……]

What types of parts are suitable for MIM?

The core capability of Metal Injection Molding (MIM) is to make complex metal parts out of high-temperature alloys with good material properties, excellent repeatability, and reasonable cost. Here are the significant factors in deciding whether a component will benefit from MIM:[……]

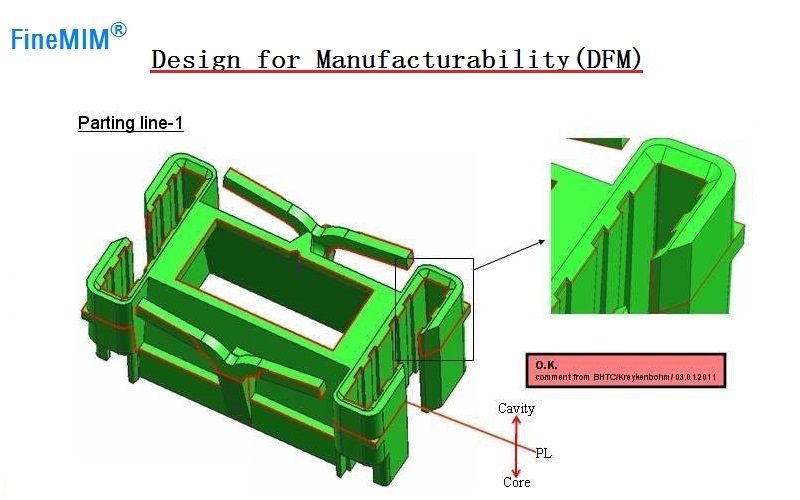

Design for Manufacturability (DFM)

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One[……]

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One[……]

General Guidelines

What makes a particular component an ideal candidate for fabrication via MIM? We break down our guidelines into four basic areas: complexity, size, production volume, and final properties.[……]

MIM technology in medical device industry

The work done by contracting manufacturing organisations (CMOs) has become the lifeblood of the medical device industry. Over a period of two decades,[……]

Metal Injection Molding in China: 2015 MIM parts sales estimated at US $725 million

The 2015 China Metal Injection Molding Industry Status Report, published by the Powder Metallurgy Branch Association of the China Steel Construction S[……]