•Annual increasing rate of Metal Injection Molding in China was over 30% since 2011

•MIM Market size is predicted to be 7 billion RMB in 2018[……]

Blog

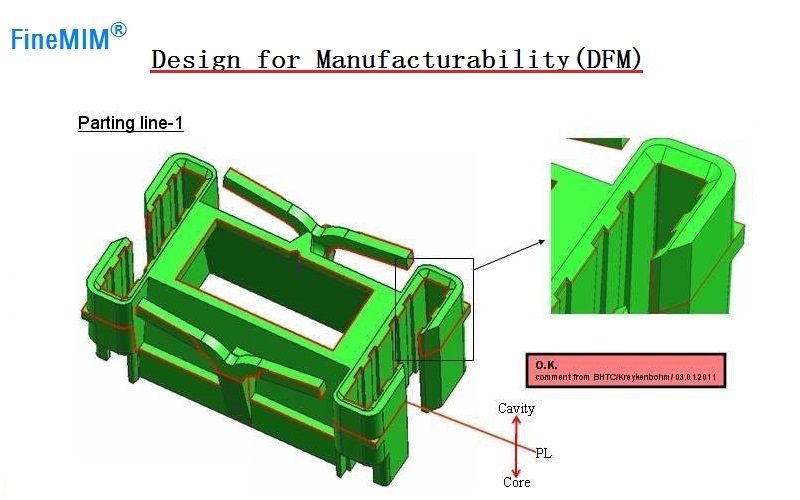

Design for Manufacturability (DFM)

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One section consists of a core which fits into an impression in the other section with uniform clearances that produce shapes with uniform wall thicknesse[……]

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One section consists of a core which fits into an impression in the other section with uniform clearances that produce shapes with uniform wall thicknesse[……]

General Guidelines

What makes a particular component an ideal candidate for fabrication via MIM? We break down our guidelines into four basic areas: complexity, size, production volume, and final properties.[……]

MIM technology in medical device industry

The work done by contracting manufacturing organisations (CMOs) has become the lifeblood of the medical device industry. Over a period of two decades, medical OEMs have effectively transitioned from a situation where many of their production requirements could be kept in-house at low cost to outsour[……]

Metal Injection Molding in China: 2015 MIM parts sales estimated at US $725 million

The 2015 China Metal Injection Molding Industry Status Report, published by the Powder Metallurgy Branch Association of the China Steel Construction Society, provides invaluable insight into the recent development of China’s Metal Injection Molding industry.

Sales of MIM parts were reported to be[……]

History of Metal Injection Molding

Metal Injection Molding (MIM) is a very recently developed process, compared to forging or casting technique.

The first studies about PIM (powder injection molding) are made in the USA and dates back to the 1920s. As the idea to plastify powdered raw materials with the help of thermoplastic addit[……]