•Annual increasing rate of Metal Injection Molding in China was over 30% since 2011

•MIM Market size is predicted to be 7 billion RMB in 2018[……]

Category: MIM

MIM (Metal Injection Molding) is an effective way to produce complex and precision-shaped metal parts from a variety of materials – without machining, from low to extremely high volume capabilities, which can be served cost-effectively and with significantly reduced lead times.

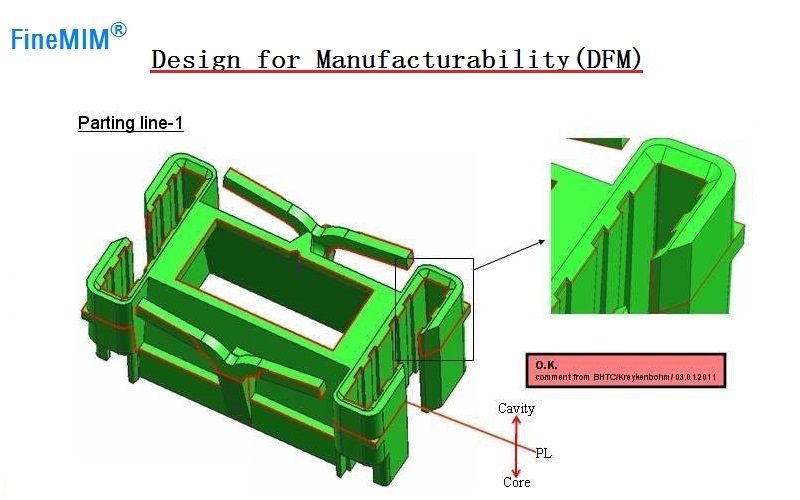

Design for Manufacturability (DFM)

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One[……]

The simplest Metal Injection Molding (MIM) shape is produced in a mold made of two sections with plane surfaces that meet to seal off the cavity. One[……]

General Guidelines

What makes a particular component an ideal candidate for fabrication via MIM? We break down our guidelines into four basic areas: complexity, size, production volume, and final properties.[……]

MIM technology in medical device industry

The work done by contracting manufacturing organisations (CMOs) has become the lifeblood of the medical device industry. Over a period of two decades,[……]

Metal Injection Molding in China: 2015 MIM parts sales estimated at US $725 million

The 2015 China Metal Injection Molding Industry Status Report, published by the Powder Metallurgy Branch Association of the China Steel Construction S[……]

History of Metal Injection Molding

Metal Injection Molding (MIM) is a very recently developed process, compared to forging or casting technique.

The first studies about PIM (powder i[……]